|

Like a good suit or the perfect LBD (little black dress), wainscoting and trim work are always in style…and unfortunately in short supply in many track homes. Trim work is an incredibly easy place to start with home improvements, even if you are new to the DIY scene or have limited experience with woodwork. It offers lasting value you can enjoy now and reap the benefits from when you sell. Case in point, my dining room: It’s a lovely space with lots of light and an equal amount of hideous, dated wallpaper caped with cheap oak chair rail. How do you get rid of ugly wallpaper? Cover it up! After thirty seconds of consideration I realized I had two options…scrape and re-texture or cover it up. It was a no brainier. I’ll take the smell of fresh cut wood and gorgeous wainscoting any day over messy chemicals.

1. Plan your wainscoting style! Before you start, hit up Pinterest for some ideas (click HERE to see my board for this project...it's Pinterest y'all, I got a little distracted so there are some other gorgeous ideas in there too, including paint colors) and find a design that suits your taste and complements the style of your home. I'm seriously in love with beadboard and had originally planned on using it in this dining room; however, this is just isn't sort of house and it would have looked contrived and out of place. Find the sweet spot between what you love and what works with the style of your home. 2. Measure and go shopping! Head to your local hardware store and pick out the pieces you want to use. Purchase just enough to make one square; take it home, and tack it to the wall or lay it out on the floor so you can spend a couple days looking at it. This can save you so much headache later on when you get halfway through your project and decide you want a slightly different style. Once you've settled on a design, go ahead and purchase all the material you'll need...measure carefully and buy extra! Tips:

I've looked at tons of the wainscoting "kits" and while I'm sure they have a place, it's just not in my life. I think wainscoting should be unique to the space, and creating your own design and buying the material piece by piece gives you that flexibility...both in design as well as installation options. When you create your own design it's easier to work around the unique challenges of your space.

4. Prep your space and get your tools ready First of all, if you've never used power tools and are about to stop reading, PLEASE stick with me! I know exactly what you are thinking..."I don't own power tools, they are expensive, and I'll probably break something or chop off a finger." But I promise you, if you have even a slightly crafty bone in your body, have used a paper cutter, or ever enjoyed scrap booking you can totally do this! And you don't have to buy the most expensive brands with the most features; we're using just a few very basic tools, and it's an investment that will last you for years! ~ EQUIPMENT CHECKLIST ~

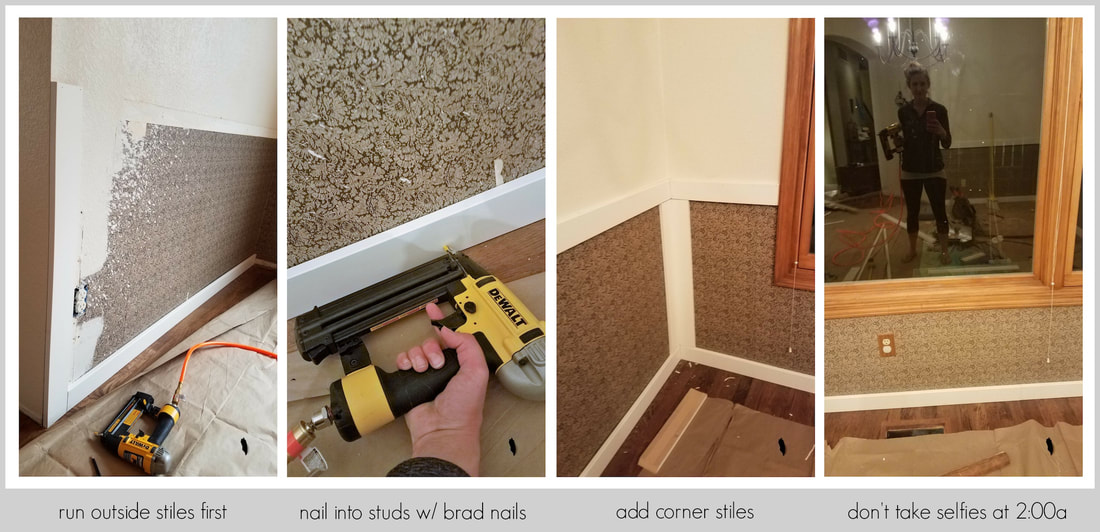

5. Run your rails Start by running your outside stiles since you will want to but up to those; then run all of your bottom and top rails, starting at one end and working your way around the room. Yes, that's me in the window at like 2a, working blissfully through the uninterrupted wee hours of the night. Sleep is overrated. Wainscoting is not! ~ MITER CUTS ~

6. Add your stiles Go ahead and cut all of your styles and prop them up in position; due to varying wall lengths you likely won't be able to get all of your panels the exact same size, but you will be able to tell visually if it looks good, or if you want them closer or further apart. The window area gave me so much grief; in additional to creating some odd shapes the silly thing isn't even centered on the wall! My original plan for panel width also had to change due to an outlet that was smack dab where I needed to place a stile. Ultimately I ended up with much wider panels than I'd originally thought becasue it just felt better in the space and made the room look larger. Use your miter saw to cut your stiles, and be sure your blade is at exactly 90 degrees! You will want the seam where the stile meets the top rail to be as tight and square as possible. Attach stiles to the wall with your brad nailer. 7. Cut your panels If you are installing over a nice clean wall and trying to save a little money this is an optional step. If you don't have a lot of texture on your walls you can let the wall itself show through as the panel. It's not going to look quite as tailored and you will be able to tell it's drywall rather than actual paneling, but it can still look good, especially if you plan to do a two tone paint design, with your trim one color and the "panels" another.

Before cutting, check which way your plywood sheets bow; you want to cut your panels so that the the edges bow toward the wall, with the center bowing out towards you. This will ensure that there won't be additional outward pressure put on your finish trim...we will be securing the finish trim with tiny pin nails, so we don't want any unnecessary pressure which could make it come loose over time. Cut one panel at a time; air on the "fat" side, test for fit, and trim down as needed. Use a pocket rasp to shave off a few millimeters at a time to ensure a perfect fit (or to smooth rough edges). Once panel fits perfectly, mark and cut holes for outlets as needed. I punched a pilot hole with with the drill, then used an orbital jigsaw to cut the rest of the whole (though you could use any small hand saw and I'm sure a real carpenter would have a better suggestion). When your panel is completely ready for install:

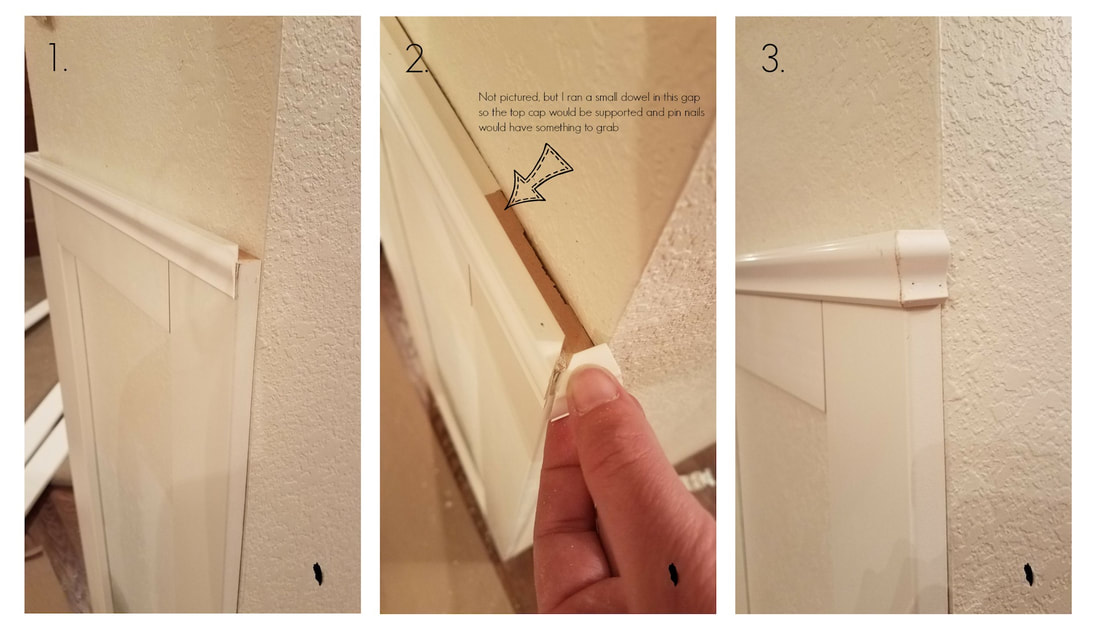

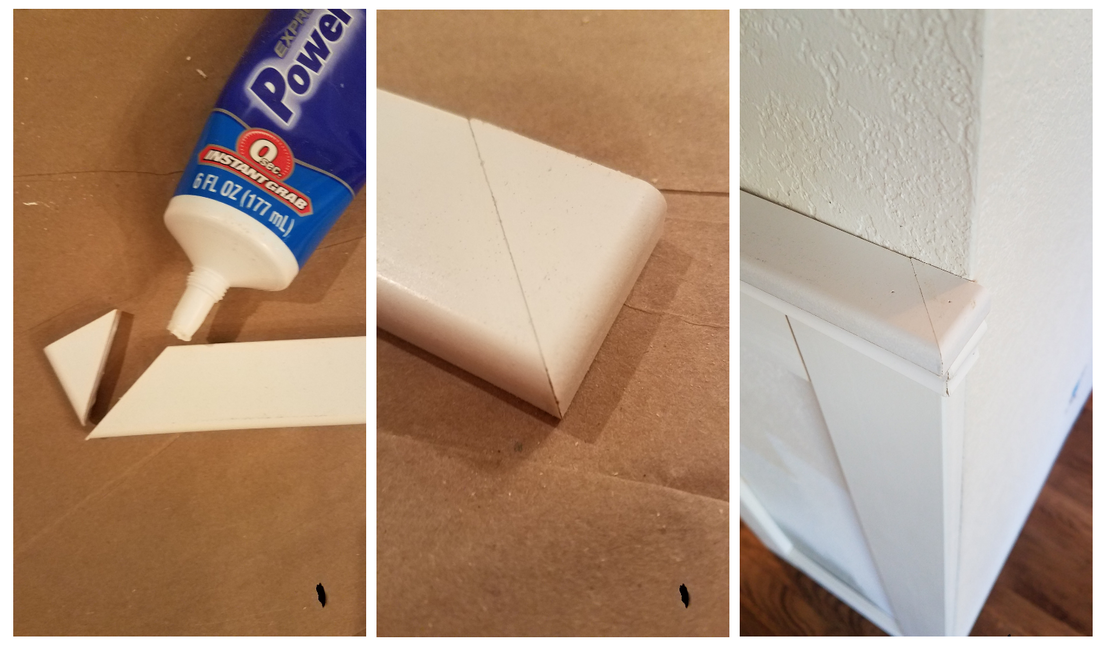

8. Add your inside trim 9. Add your crown and top cap I had so much fun putting this on I nearly forgot to take pictures! I was using two types of cap molding since that's what I could find in stock at my local Home Depot and I liked the look of the layers together...so, my "cove" had to go on first and then the actual cap. Typically you'd add the cap first (the flat piece on top) and then the cove beneath it. When you start, begin with your exterior corners so that any joints are further along down the wall and not as noticeable. Use your pin nailer to secure each piece as you go. ~ HOW TO MANAGE EXTERIOR CORNERS ~ When working with exterior corners you will want to ensure you have a finished edge showing! To do this, simply miter the main piece of material as pictured (1) and then cut a small section to fit in along the end (2). You'll have a lovely finished edge showing from every angle (3), and your friends will be amazed at your skill and attention to detail. Just don't tell them how easy it was! For the top cap I completed the exterior corners like this: 10. Polish off your trim and caulk

Tips for perfect caulking:

11. Prime and paint

12. Admire your handiwork, take lots of pictures, and share them with me! Have fun moving everything back into your space and decorating! And don't forget to leave me comments and share photos :-) What's your next project?

0 Comments

Leave a Reply. |

OneNest News

Make sure to catch all the latest One Nest news, updates and posts by following us on Facebook and Twitter! Archives

May 2019

Categories

|

RSS Feed

RSS Feed